Eric Anthony Baker

PROGRAMS:

COMPANIES:

LOCATIONS:

Kennedy Space Center, Launch Complex 39

POSITIONS:

Rockwell International, Space Shuttle Orbiter Data Processing System (DPS) System Engineer

Rockwell International, Space Shuttle Orbiter Test Project Engineer (TPE)

Lockheed, Space Shuttle Orbiter Test Project Engineer (TPE)

United Space Alliance, Space Shuttle Orbiter Test Project Engineer (TPE), Orbiter OV-103 Lead TPE

COMMENTS:

My aerospace career began with the United States Airforce in 1969. Trained as an Avionics Navigation systems technician working on T-37 and T-38 training aircraft at Craig Air Force Base in Selma, Alabama and on F-4D and AC-130 aircraft at Ubon Royal Thai Airforce base. The equipment worked on was during a transition from vacuum tube electronics to discrete transistors to the very earliest integrated circuit computer systems on jet aircraft.

After four years in the Airforce and civilian technician work I returned to college on the GI bill and trained as an Electronics Technology Engineer. Having been following the space program since the days of Mercury, Gemini and Apollo the start of the Space Shuttle program was quite interesting. While attending Florida International University in Miami, FL a fellow student made me aware that Rockwell was hiring as the prime contractor for orbiter processing at Kennedy Space Center. Interviewing in the spring of 1980 led to a position with Rockwell in June of 1980 working as an Orbiter Data Processing Systems engineer. DPS was responsible for test and checkout of the orbiter on board computers and the main man machine interface of orbiter keyboards, Multifunction CRT displays and flight instruments. When the Canada Remote Manipulator System was added DPS was the system responsible for Arm checkput and installation. When a Heads Up display system was added to the orbiters DPS was responsible for that new system checkout.

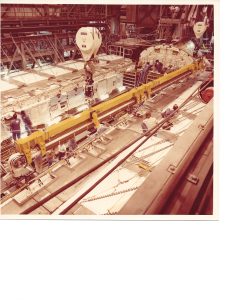

Remote Manipulator in orbiter payload bay

After 4 years working Orbiter DPS I was able to transistion to the Test Project Engineering office. Test Project Engineering (TPE) was responsible for technical oversight of all Orbiter systems during powered activity. TPEs operated from the Integration (INTG) console in the Launch Control Center (LCC) at Launch Complex 39. TPEs monitored orbiter and full space shuttle stack power up, power on test and checkout and power down for the Orbiter Processing Facilities (OPF), the Vehicular Assembly Building (VAB) High Bays 1 and 3, and Launch Pads 39A and 39B. TPEs had signature authority for all Orbiter and Space Shuttle power on testing, checkout and trouble shooting of anomalies along with the Vehicle Test Conductors, the System engineers and the Safety Engineers.

TPEs were also responsible for the integration of the Extravehicular Mobility Units (EMU, space suits) along with other system engineers for each shuttle flight.

TPE vehicle leads were responsible for the integration of the Flight Crew engineering briefing prior to each flights Countdown Demonstration Test (CDDT) and the Launch Countdown.

My last launch as TPE Lead for OV-103, STS-131, with co-workers in Firing Room 4, Launch Control Center.

Visiting my orbiter in the Udvar-Hazy Center in Virginia.

At the Space Shuttle Monument in Titusville, Florida